Ultimate Mistake Prevention Shutter System

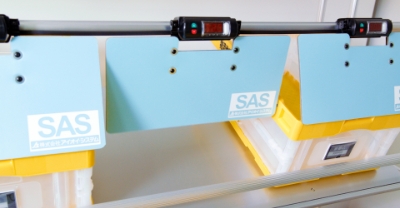

The Shutter Assorting System (SAS) is a small-opening sorting system equipped with the newest light modules with shutters. The system is compatible with both put to light and pick to light, and nearly eliminates sorting mistakes in all cases. The system improves accuracy and efficiency, reduces training costs, and can be used to quantify processes.

Issues&Solutions

- e-commerce and other workplaces where sorting errors are not tolerated

- FA sites where important safety parts and the like are managed and sorted, and where errors are not tolerated

- Workplaces where pharmaceutical products are handled

- High accuracy requirements by shippers/vendors/users

- Desire to improve operational efficiency by omitting inspections

- Searching for a revolutionary system that visually facilitates work for operators

SAS solves these types of problems in the field.

It is very simple to use. The operator scans the barcode of an object, inserts the indicated number of items into the opening behind the open shutter, and presses the “input complete” button to close the shutter. The system can be put to use immediately after installation—there is no need to spend time on training. This is an optimal system for e-commerce and sorting by store.

Prominent Features of the Shutter Assorting System (SAS)

-

Sorting function

When the barcode of an object is scanned, the light module of the target opening lights up, and the shutter opens. The computer screen shows a progress bar to enable the operator to view the process of operations in real time.

-

Opening assignment function

Sort the operation instruction data by number of items per opening, and assign high-volume items to the openings closest to the operator. The assignment results can be confirmed on the screen that shows the list of recipients. This leads to better workability by streamlining the movement of operators.

-

Output operation results (CSV export)

Output operation result data into CSV files. Operation result data is added to the end of the operation instruction CSV file.

-

Re-display function (find lost items)

This function re-displays completed openings during sorting operations. Any discrepancies between the status on the system and the actual status can be resolved immediately.

-

Operation data viewing function

Operation data can be viewed by recipient, item, and operation status (incomplete/complete).

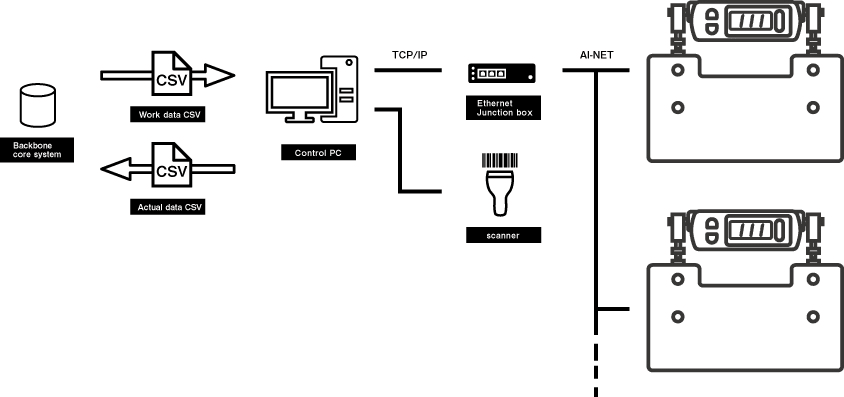

SAS (Shutter Assortment System) can be provided as a turn key system with a packaged software.

The system can be easily introduced onsite with a short lead time because the necessary functions for sorting operations are built in as standard features.

We also propose optimal system configurations and provide customized systems for various customer environments.

Equipment Configuration

Features of Pokayoke Gate LM

-

01Shutters drastically reduce errors

Compatible with both put to light and pick to light. Expect improved accuracy and a drastic reduction in shipping mistakes. An inward-opening type is also available.

-

02Detailed settings for specific purposes

Set angle, speed, shutoff time, and more. It is easy to adjust the system to suit the details of your operations.

- Angle: Range of 270°, can be adjusted manually to fit conditions on the floor

- Speed: Can be adjusted on three levels

- Shutoff time: Can be set in units of 0.1 seconds

-

03Large, easy-to-push button design

The buttons are large and easy to operate. Highly visible LEDs display up to three digits.

-

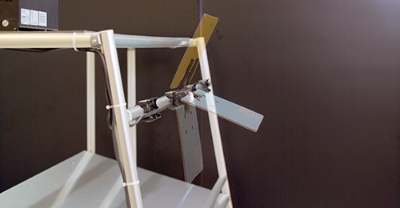

04Easy installation with fewer wires

Installation and maintenance are easy—no connectors required. Duct, flat, and pipe base installation options are available.

-

05Equipped with the newest functions that can be set using a smartphone or HHT (handy terminal)

Use NFC to set addresses, angles, and other settings. It is possible to set or change settings even when the light modules are not connected to a power source.

-

06Safety-conscious design

Shutters relax automatically on impact by operators for a safe working environment. Normally, shutters are locked so that they do not open. These shutters can be unlocked with a single touch for easy collapsible container removal and more.

We also propose optimal system configurations and provide customized systems for various customer environments.